Varnishes

Varnish is often associated with wood. However, varnishes are also used on paper.

Paper varnishes are applied to paper stock to give the page a smooth and consistent texture as well as having the added benefit of sealing the printed material to help preserve it better.

High-quality books and magazines usually have a paper varnish applied to their pages.

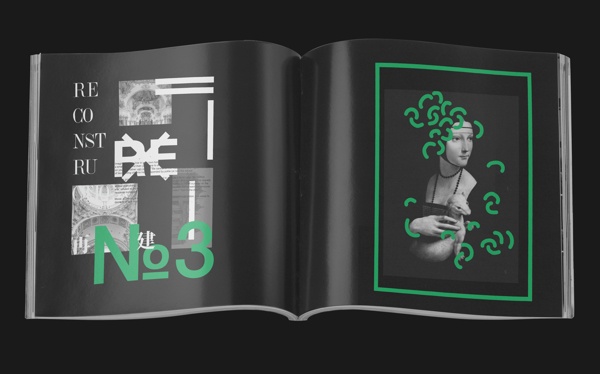

Varnishes can be glossy, as the example below shows:

Or matte (below):

Typically, varnishes are applied to the entire printing surface when a page needs to be robust but without adding too much weight to the paper stock, making it suitable for magazine pages, magazine covers, and brochures.

Lamination

Lamination adds a layer of protective coating (usually some type of plastic), often glossy or matte, to the printed surface while also improving its sturdiness and water resistance.

Lamination also has the added benefits of improving the tactile feel of the printed surface, lending it a smooth finish.

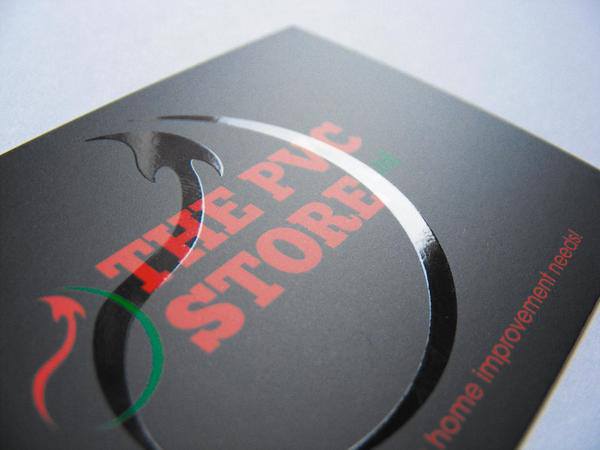

If a high gloss laminate is applied to the printed surface, photos and images appear to have more contrast and have better sharpness, as shown below:

Matte laminated prints are more subdued but add a very luxurious and elegant finish to the printed surface:

Lamination is not unlike varnishes. Typically, lamination is used if sturdiness is required such as for business cards and soft covered books. Also, in my experience, lamination tends to be one of the more expensive print finishes.

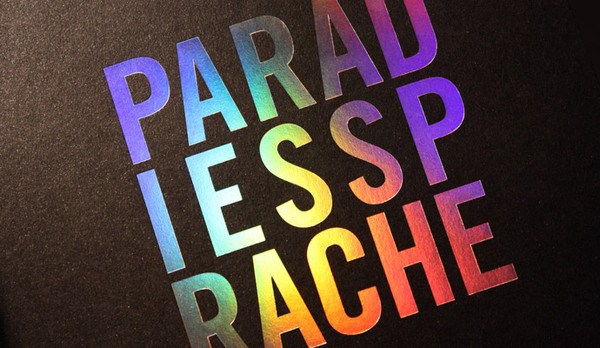

Spot UV Varnish

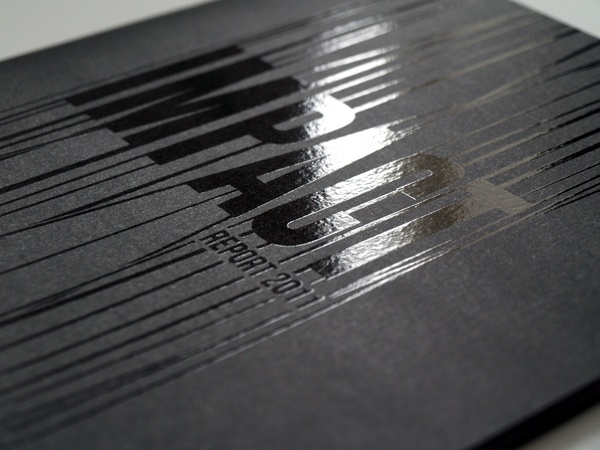

Spot UV varnishes are paper varnishes applied to the printing surface and is cured or hardened by UV light during the printing process. This results in a glossy coating on the surface of your print, as shown below:

UV varnishes are usually used as a spot application where only specific parts of the page get a UV varnish.

This effectively gives texture and focal interest to different areas of the printing surface while leaving other areas untreated.

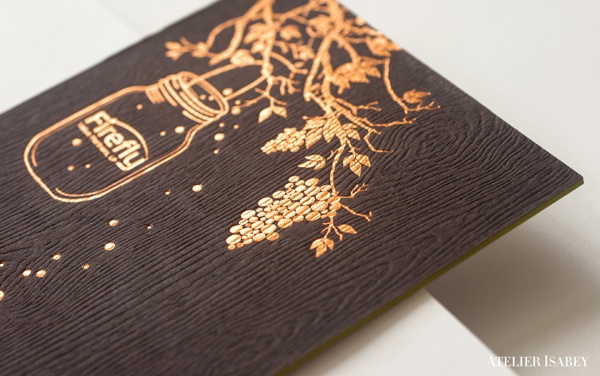

Foil Stamping

Foil stamping is the use of a malleable metallic material applied to the print surface by using heat and pressure.

Foil stamping adds reflective properties to various elements of your design and can serve to add a bit of luxury to a design.

Typically, it is used on text and the logo on the page or when certain elements call for it.

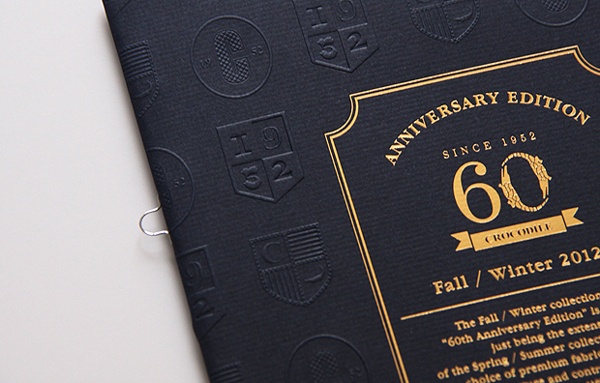

Embossing

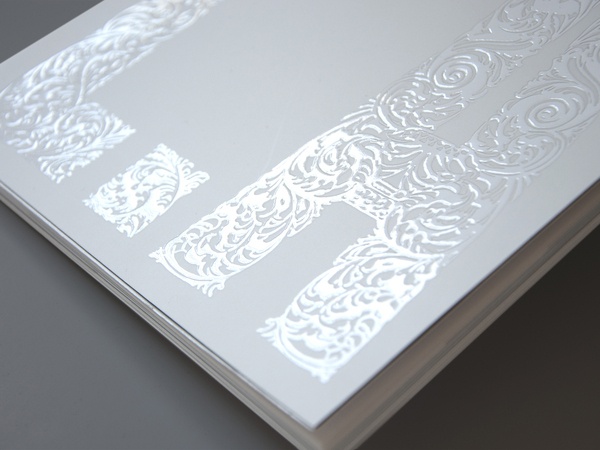

Generally, embossing refers to raising parts of the page for emphasis and texture.

This print finish adds physical depth to the embossed elements and thus, shadows and highlights are also produced in the design.

Embossing also adds a tactile dimension to your design. Images and text are literally felt.

Often, embossing can be combined with other printing techniques such as foil stamping to enhance the effects of both techniques.

Letterpress

Letterpress printing is one of the oldest printing techniques available. Some printers may call letterpress printing by the term debossing.

A letterpress is used to depress or indent certain portions of the page. It can be seen as the opposite of embossing.

Traditionally, the letterpress technique was used only for applying ink on a page as a form of relief printing and usually only for text. But it has evolved to also include pressing logos and other design elements directly into the paper.

Conclusion

There are a lot more finishes to consider such as die cutting, folding, and laser cutting. However, some methods aren’t exactly cheap and so having a budget in mind is always helpful when deciding what to use on a certain project. Print finishes are great for giving designs that extra push to go from good to great. A good print finish can sometimes make or break a good design. The challenge, therefore, is finding the right applications and the perfect balance of their use.

No comments:

Post a Comment